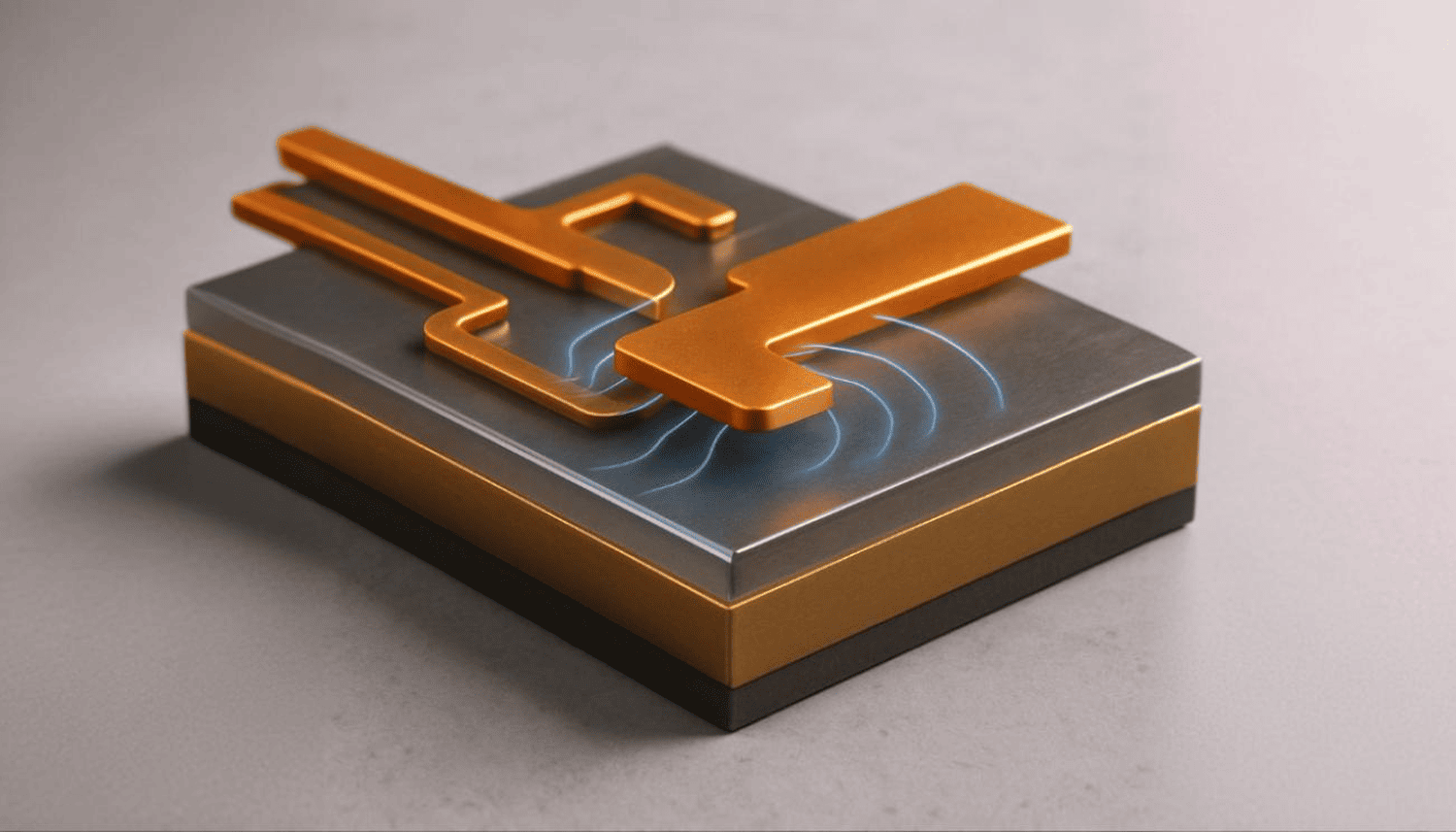

A large and continuous ground plane is a crucial practice to minimize impedance, reduce EMI, and mitigate signal coupling issues in thin film devices. A ground plane provides a low impedance path for the return currents of the signals, which helps to minimize the loop area, reduce ground noise, and enhance signal integrity by maintaining a stable reference potential. It also acts as a shield, reducing electromagnetic interference (EMI) by providing an effective ground return path and preventing the propagation of unwanted electromagnetic fields. Additionally, a well-designed ground plane helps to isolate and minimize crosstalk between adjacent signal traces by providing a solid reference plane that reduces the electromagnetic coupling between traces.

A large and continuous ground plane is a crucial practice to minimize impedance, reduce EMI, and mitigate signal coupling issues in thin film devices.

- Low Impedance Path: A large ground plane provides a low impedance path for the return currents of the signals. This helps to minimize the loop area, reduce ground noise, and enhance signal integrity by maintaining a stable reference potential.

- EMI Mitigation: A continuous ground plane acts as a shield, reducing electromagnetic interference (EMI) by providing an effective ground return path and preventing the propagation of unwanted electromagnetic fields.

- Crosstalk Reduction: A well-designed ground plane helps to isolate and minimize crosstalk between adjacent signal traces by providing a solid reference plane that reduces the electromagnetic coupling between traces.

- Thermal Management: The large metal area of the ground plane helps to dissipate heat from the components, which is especially important for high-power devices.

- Reliability: By providing a low impedance path for the return currents, the ground plane helps to reduce the risk of ground bounce and other signal integrity problems.

Achieving a Large and Continuous Ground Plane

Single Solid Plane

- Design the substrate with a single, continuous ground plane that covers the majority of the substrate area.

- Avoid splitting or discontinuities in the ground plane unless necessary for specific circuitry requirements.

Minimize Ground Plane Splitting

- If splitting the ground plane is unavoidable, ensure proper routing and return paths between the split sections.

- Implement stitching vias or bridges to maintain connectivity and reduce impedance between the split ground planes.

Avoid Signal Traces in the Ground Plane

- Keep signal traces away from the ground plane to minimize coupling and interference.

- If traces must cross the ground plane, use a bridge or clearance in the ground plane to maintain isolation and prevent coupling.

Component Placement

- Plan the placement of components on the substrate to maximize the coverage of the ground plane.

- Avoid blocking the ground plane with components or routing traces that would limit its continuous nature.

Via Placement

- Strategically place vias to connect the top and bottom ground layers, ensuring a low impedance return path and maintaining a continuous ground plane throughout the substrate.

- Use an adequate number of vias to minimize ground impedance and optimize the return paths.

Signal Layer Arrangement

- Consider the arrangement of signal and ground layers in a multilayer substrate design.

- Place the ground layers adjacent to signal layers to provide efficient return paths for signals and reduce crosstalk.

High-Quality Connections

- Ensure proper grounding connections between the ground plane and the components, such as using vias with sufficient diameter, low impedance paths, and good solder joints.

Use a Low-Loss Substrate

- The substrate material can have a significant impact on the impedance of the ground plane.

- Choose a substrate material with a low dielectric constant (Dk) and low loss tangent to minimize the impedance of the ground plane.

Optimize the Ground Plane Thickness

- The thickness of the ground plane can also affect the impedance.

- A thicker ground plane will have lower impedance, but it will also be heavier and more expensive.

- The optimal thickness will depend on the specific application.

Use Stitching Vias

- Stitching vias can be used to connect the top and bottom ground layers, which helps to improve the continuity of the ground plane and reduce impedance.

Apply a Solder Mask

- A solder mask can help to protect the ground plane from corrosion and improve the electrical conductivity of the ground plane.

In conclusion, a large and continuous ground plane is a crucial practice to minimize impedance, reduce EMI, and mitigate signal coupling issues in thin film devices. By following the tips outlined in this article, you can design a large and continuous ground plane that will help to improve the performance, reliability, and EMI immunity of your thin film device.

Here are some of the key points to remember:

- A large ground plane provides a low impedance path for the return currents of the signals, which helps to minimize the loop area, reduce ground noise, and enhance signal integrity by maintaining a stable reference potential.

- A continuous ground plane acts as a shield, reducing electromagnetic interference (EMI) by providing an effective ground return path and preventing the propagation of unwanted electromagnetic fields.

- A well-designed ground plane helps to isolate and minimize crosstalk between adjacent signal traces by providing a solid reference plane that reduces the electromagnetic coupling between traces.

- The thickness of the ground plane can also affect the impedance. A thicker ground plane will have lower impedance, but it will also be heavier and more expensive. The optimal thickness will depend on the specific application.

Leave a Reply