What We Help You Build

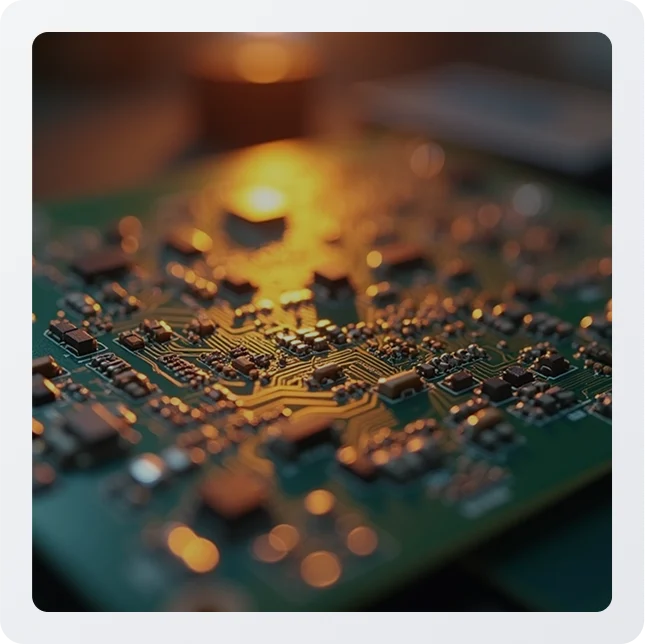

Precision-engineered microdevices tailored to your specific performance, material, and application needs.

Filters, dividers, IPDs, couplers, circulators, and other high-performance RF devices.

Precision-engineered with vias, metallization, and

surface customization.

Gold-filled vias and near hermetic sealing on sapphire for high-reliability medical implants.

microfluidic flow cells and ultrasound imaging for life sciences.

Extreme thermal management on synthetic diamond for high-power.

Multi-layered, bendable circuits with embedded functionality for wearable applications.