At millimeter-wave frequencies, most RF failures don’t announce themselves as failures.

They appear as small degradations:

slightly worse isolation,

unexpected lot-to-lot variation,

performance that looks acceptable but no longer inspires confidence.

This is particularly true for directional couplers, where performance depends not on absolute accuracy, but on precise cancellation between nearly identical signal paths.

When directivity erodes, designers often suspect models, layouts, or calibration. Manufacturing is usually examined later—after the pattern repeats.

In practice, the first assumption to fail is often much simpler.

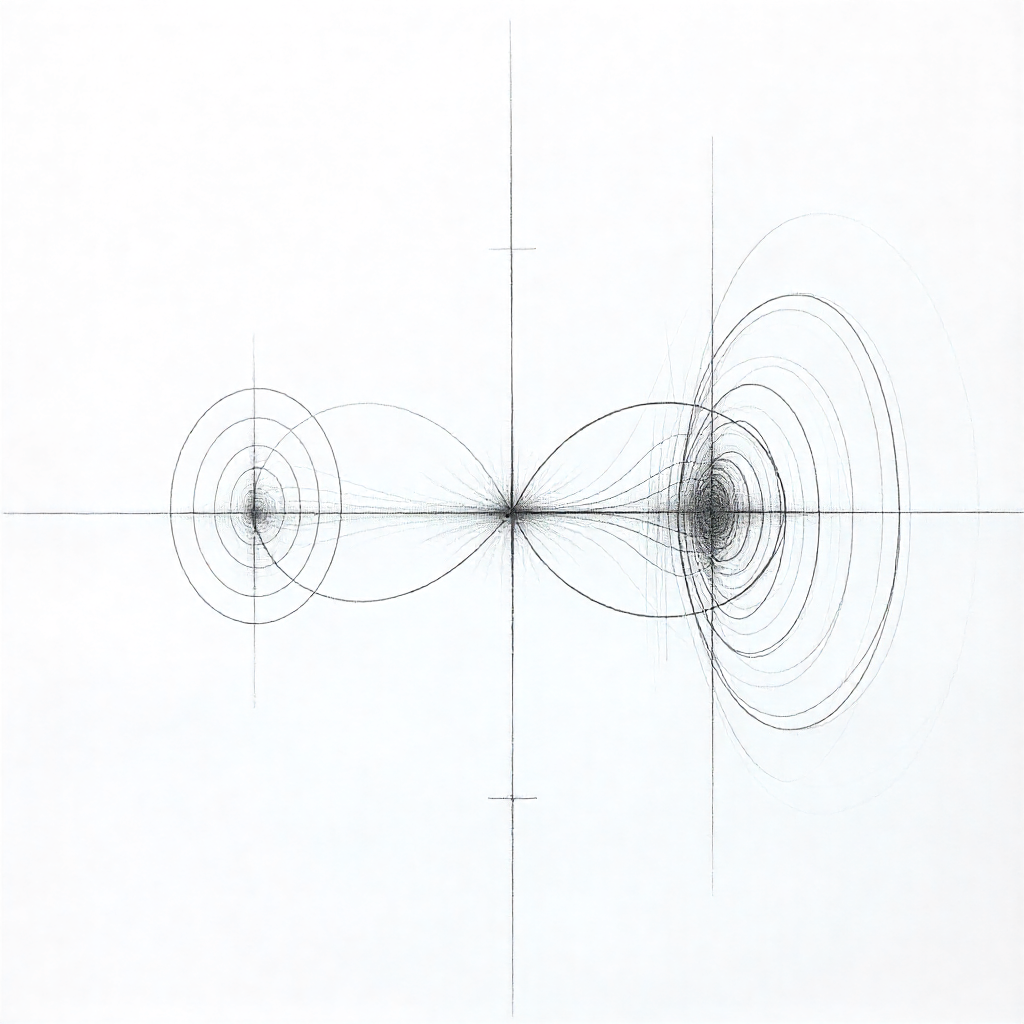

Directivity Is a Symmetry Problem

Insertion loss tolerates imperfection.

Return loss tolerates approximation.

Directivity does not.

It is a difference measurement. Two paths must remain matched in:

- impedance

- electrical length

- parasitic coupling

When cancellation is the mechanism, small asymmetries matter more than large errors elsewhere.

At mmWave frequencies, many of those asymmetries enter the system through vias.

The Via Stops Being “Electrically Short”

Below ~10–15 GHz, vias behave like benign parasitics.

They are short enough that imperfections average out.

Above ~30 GHz, that intuition quietly breaks.

A via becomes:

- a three-dimensional boundary condition

- a short distributed structure

- a region where fields concentrate and reorganize

The via is no longer just a connection.

It becomes part of the RF path.

At that point, the details begin to matter.

What Changes Electrically — Even When Drawings Don’t

Several via characteristics that were once secondary become decisive:

Taper

Small changes in diameter from top to bottom alter local impedance and field distribution. What matters most is not average diameter, but how the transition behaves near the RF launch and ground reference.

Sidewall condition

At mmWave, current flows along the via wall. Roughness, recast layers, and surface chemistry change the effective electrical length and current distribution. These effects rarely show up as excess loss. They show up as phase imbalance.

Aspect ratio

Higher aspect ratios amplify everything:

plating non-uniformity,

taper sensitivity,

depth-dependent roughness.

The via behaves less like a lumped element and more like a stack of small discontinuities.

Material interfaces

Copper vs gold fill, oxide layers, and adhesion interfaces change how current crowds and redistributes. Two vias with identical dimensions but different interfaces are not electrically identical at these frequencies.

None of this violates electromagnetic theory.

It violates the assumption that vias are simple.

Why Simulation Rarely Warns You

Most EM simulations assume:

- smooth cylindrical vias

- uniform conductivity

- ideal symmetry

Fabrication rarely delivers that combination.

The simulation answers the question:

“What if geometry were ideal?”

Hardware answers a different one:

“What if geometry is merely acceptable?”

At mmWave, the gap between those two questions becomes visible.

Why This Shows Up as a Reputation Problem

Directivity degradation is rarely catastrophic.

It is subtle, contextual, and difficult to explain.

Products may still ship.

Specifications may still be met.

But confidence erodes.

For companies whose reputation depends on consistent isolation—this is not a yield issue. It is a trust issue.

Customers remember inconsistency more clearly than they remember averages.

The Practical Lesson

At millimeter-wave frequencies, vias are no longer background details.

They are RF boundaries whose geometry must survive fabrication with intent, not just tolerance.

This does not require exotic processes.

It requires recognizing which assumptions are no longer safe—and treating those features accordingly.

The uncomfortable truth is that manufacturing literacy is now part of RF performance.

Design, simulation, and fabrication are not sequential steps.

They are a single system, constrained by its weakest assumption.

The Vajra Position

Vajra Microsystems does not design couplers or RF networks.

Our focus is narrower:

to identify where physical reality quietly diverges from design assumptions at mmWave—and to help ensure that divergence does not show up in hardware.

Nothing here breaks Maxwell’s equations.

Manufacturing simply decides whether the assumptions they rely on remain intact.

Leave a Reply